Operating the New Pack Shed at Ideal

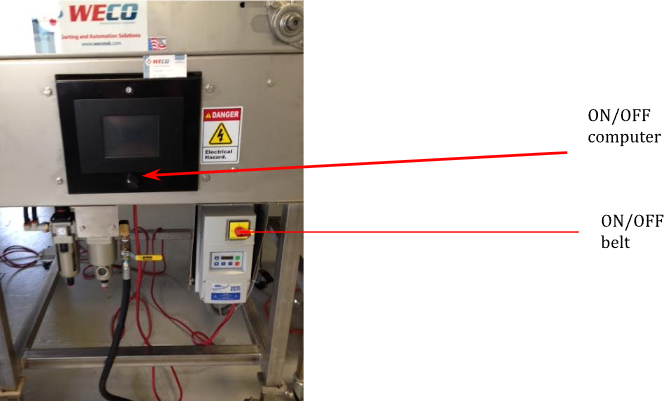

Before season begins: Call WECO to come and tighten belts and do any computer upgrades that are necessary.

1. Day before you pick make sure your cooler is on and at the temperature you want to cool the fruit from the field.

2. Turn on air conditioners in pack shed (controls near large input holes in walls). Push bottom right button until it reads COOL. Once on then you can adjust the temp up or down using the 2 buttons on the right of the box.

3. Make sure all the equipment in the pack shed is plugged into the ceiling. The sorters plug in to the electrical above them (dedicated line) and the other equipment to other electrical boxes above them.

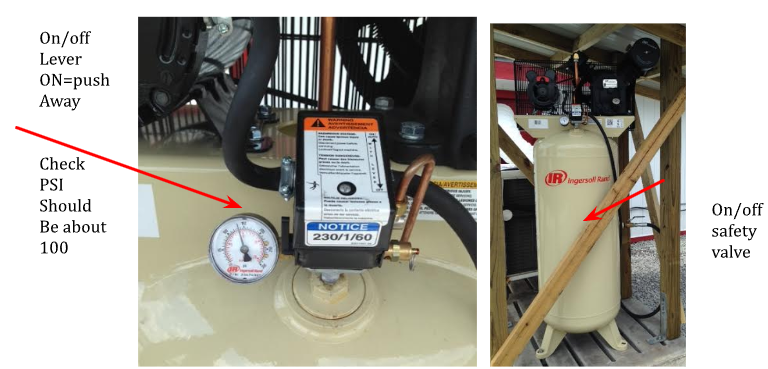

4. Make sure the air compressor lines are connected to the color and soft sorter.

5. Turn on air compressor. Go outside and on top of the air compressor sort of on the right side closest to the coolers there is a black box. Flip the leaver on the left side of that box. Make sure the shut off valve on the lower right side of the compressor is open to the hose leading to the building. Check inside that air compressor hose reel valve is also open.

6. Pick your fruit.

7. Put your fruit in the cooler to cool down.

8. Turn the line on backwards.

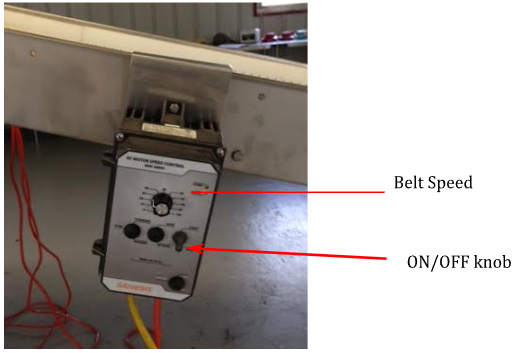

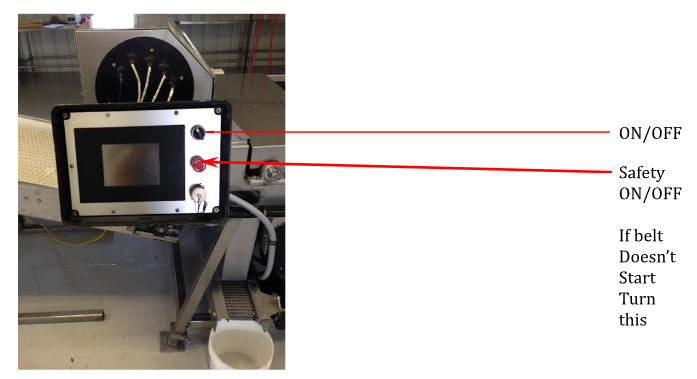

9. Turn on the white conveyor belt-double flip the switch to one. You can adjust the belt speed using the knob on top middle labeled % speed. I recommend 29.

10. Turn on color sorter. Turn top black knob to right. If the belt doesn’t start turn the red knob below it to the right (this is the safety belt turn on knob). Make sure the psi gauge reads 70 (it definitely should not be above 100). Make sure the shut off valve to the air compressor is open.

11. Turn on the soft sorter. Turn the black knob under the screen to the right to turn on. Then turn the red knob below the screen to the right to turn the belt on. Check the psi here as well. Make sure the shut off valve to the air compressor is open too.

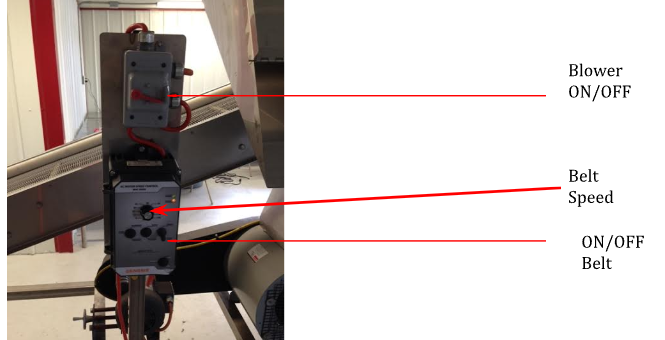

12. Turn on the blower. Turn on the belt (double click) using the knob on the lower box on the right. You can adjust the belt speed. Lower is better as the fruit tends to not catch and fall back down. The blower vibrations makes this worse. Then turn on the blower by flipping the large red lever up/to the left.

13. Place fruit in the hopper. We had trouble with the fruit catching on the belt so we used a Styrofoam block and loaded the fruit in front of it. Pour the fruit evenly across the belt. Hold on to Styrofoam. Don’t let it get sucked up into the blower.

14. Once you are done running fruit turn all the equipment off. Start with the blower, then sorters, and inspection belt. Make sure the air is off as well.

15. Clean down equipment. For the belts use water and a wet towel. You may need to run the belts to clean them. Watch your towel and hands/fingers/hair. Make sure to let it dry. Do not get the screens/computers/electrical wet!

16. To clean the blue keys on the soft sorter use a credit card to scrap off the gunk. Clean onto the keys, between like floss and under. On the blue belt that delivers out the kicked fruit use a damp towel (no soap).

17. To clean the cameras on the soft sorter use a damp towel! Then use the micro towel to remove water splotches from the cameras.

18. Let everything dry!

End of season:

When done clean the machines well and call WECO. They will come out and loosen the belt for the off-season. We can cover the machines with plastic drop cloths if we want.